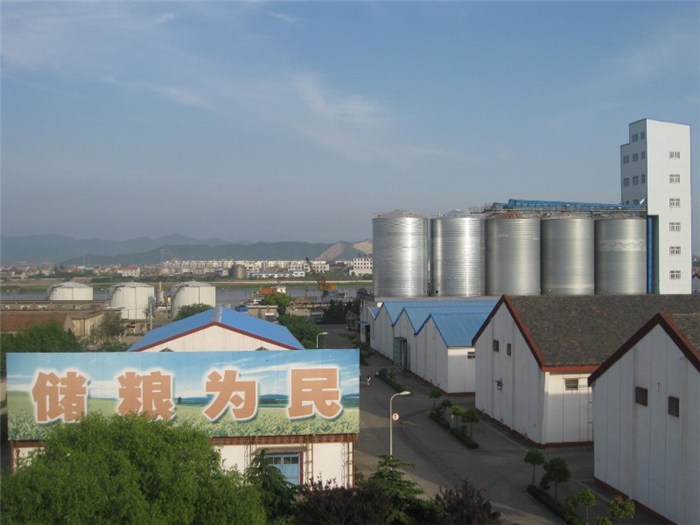

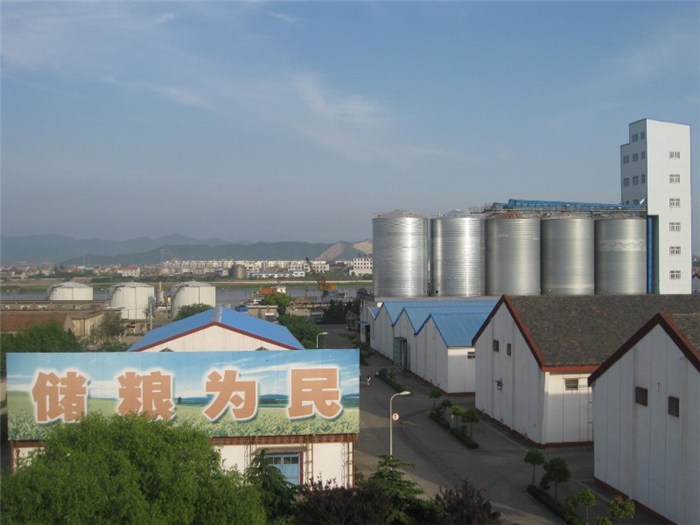

Steel Plate Silo is mainly used for storing powder and granular materials such as cement, fly ash, slag micronized powder, clinker, grain, etc. In 2013, it has been successfully used for storing liquids such as sulfuric acid. The development of steel plate silo has a history of more than 100 years, first widely used in foreign countries, the application of grain storage steel plate silo originated in the early 20th century, the end of the 1970s, in the foreign grain industry, the steel plate silo almost replaced any type of

Grain Silo storage steel plate silo. Steel plate silo can store granular, powder, grain, oil, food, brewing, coal, building materials, such as spiral steel plate silo, in the field of industry and agriculture, urban and rural areas and environmental protection industry and other fields are widely used.

Material unloading, conveying using Roots fan or air compressor air supply, fluidization device inflated by the self-flowing angle, the material is very smooth unloading into the gallery conveying device.

As this large steel plate silo adopts the design concept of integrating gas fluidization, gas homogenization and gas discharge and conveying, i.e. the principle of one gas for multiple uses, it can save a large amount of gas source. Due to the consideration of the long storage period of cement and the increase of capacity and weight, the unloading adopts medium-pressure air as the gas source, and the center area and the conveying surge pipe adopt the low-pressure gas source of Roji fan. The comprehensive power consumption of gas homogenization, unloading and conveying of tons of cement is about 0.3 degrees, and the power consumption will be relatively increased if the cement is stored for a long time. The effective diameter of the large steel plate warehouse can be up to more than ten meters to dozens of meters, the height to diameter ratio is generally about 1:1. The body of the warehouse is cylindrical steel plate warehouse manufacturers, the top of the warehouse is a round warehouse in the shape of a ball missing. The wall of the warehouse is made of welded steel plate; its ball-shaped top of the semi-circular body is formed through a special structural design and a combination of multiple arch beams and unique architectural structure, and its reasonable architectural structure so that its dome has the carrying capacity. The shape of the bottom of the library is concave, using the principle of wedge force pressurization design, in different climatic conditions and geological structure, its design parameters are different.

If the civil foundation of the large steel plate warehouse is a pile raft foundation or composite foundation, pay attention to the concrete pile foundation when the earth and stone machinery excavation, and do not use large equipment when digging between piles. Mechanical digging to the base elevation to maintain 300-500mm residual at the residual amount of manual digging. Strictly prohibit mechanical direct pile digging, so as not to cause pile breakage damage to the pile foundation. Pay attention to the protection of exposed pile head in the cleared area. After excavation shaping, a drainage ditch and water collecting pit should be dug along the perimeter of the bottom of the side pit. 4. If the foundation of the large steel plate warehouse needs to be excavated on a slope, the obstacles in the excavation area should be cleared before excavation, when piling up soil or materials on the upper side of the excavation slope as well as moving the construction machinery, it should be a certain distance away from the edge of the excavation in order to guarantee the stability of the side slopes; the materials and soil should be piled up 1 meter away from the edge of the foundation pit and their height shouldn't be more than 1.5 meters. The height should not exceed 1.5 meters. 5. large steel plate warehouse foundation earth excavation dust, construction site earthwork should be taken to prevent dust measures should be used to sprinkle water and other wet work measures in windy weather shall not be carried out on the environment to produce dust pollution of earth backfill, transfer operations.

Advantages of steel plate warehouse;

First, the effect of grain storage, reinforced concrete silo in the rain leakage is not very satisfactory, the grain is very easy to moisture mold, and large steel plate silo can be very convenient to control the temperature and humidity, to prevent the deterioration of grain.

Second, less investment, large

Steel Silo weight only 1/10-1/6 of the concrete silo, low requirements for the foundation, storage of the same volume of grain, the total investment is only 50% of the concrete silo.

Third, easy to use, large steel plate silo with elevator can be automatically loaded grain, because of its lower part of the conical bottom, there is a control switch, so unloading grain is also very convenient. Fourth, long service life, large steel plate silo made of galvanized steel, not easy to rust, can be used continuously for more than 30 years, when the silo needs to be relocated, loosen the bolts can be. Super simple!

Anyang Dazheng Steel Silo Co., Ltd., founded in 2002 with a registered capital of 35.89 million RMB, is a large-scale specialized manufacturer and contractor of steel silos, steel structures, and grain machinery. The company has obtained international certifications for quality, environmental management, and occupational health and safety. It holds 3 invention patents and 54 utility model patents.

The annual production capacity of Dazheng Company is over 2 million cubic meters of steel silos and 36,000 tons of steel structures. The diameter of the steel silos can range from 2.8 meters to 30 meters. Single silo storage capacity reaches 20,000 tons. The height of multi-layer steel structure frameworks can reach 50 meters.

Dazheng has undertaken international projects in countries such as Malaysia, Vietnam, Kenya, South Africa, Eritrea, Russia, Kazakhstan, and Kyrgyzstan, establishing long-term stable cooperative relationships.